Automated Production Line | DTFPA Line

Automated Production Line

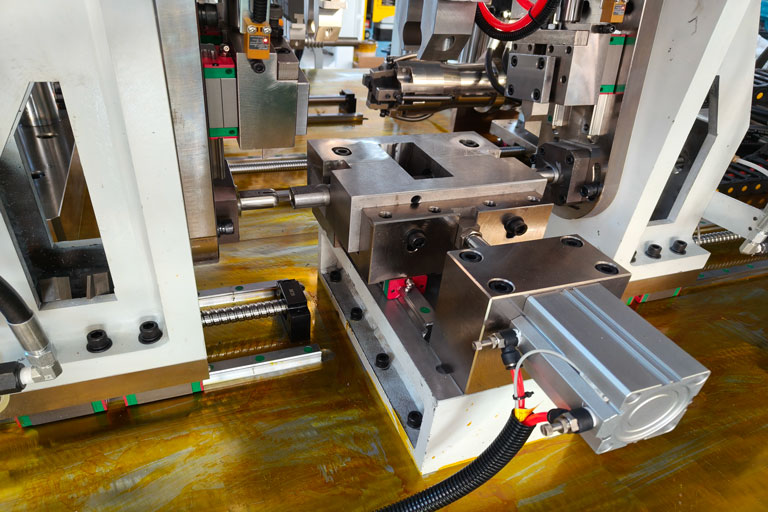

● Efficiency: Simultaneously processes both tube ends, reducing processing time.

● Precision: Ensures high-quality and accurate results with precise punching.

● Cost-Effective: Minimizes labor costs and optimizes production expenses.

● Flexibility: Adaptable to various industry needs, including automotive and aerospace.

● Consistency: Provides reliable and uniform product quality.

Automated production line with PLC or IPC which manages Feeding (Y), rotation (B) & Bending (C) in a complete automatic cycle.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

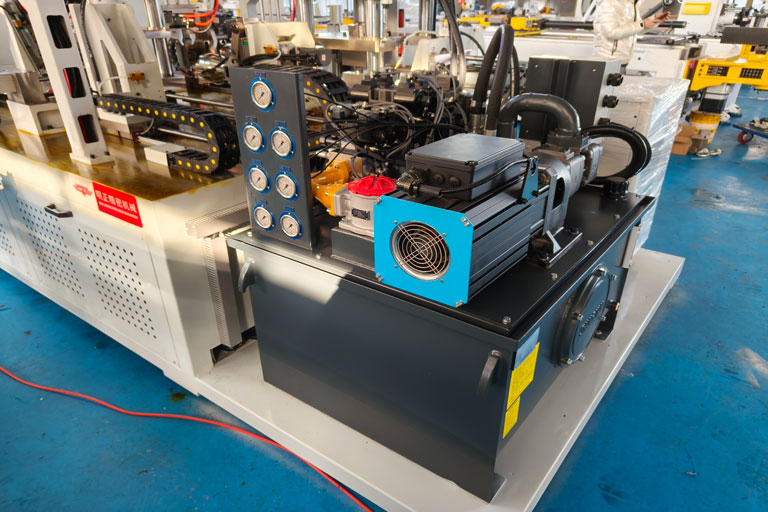

This automated production line features a compact design, advanced control system, and hydraulic precision for efficient, high-quality double-ended tube forming and punching, making it versatile and reliable for various manufacturing needs.

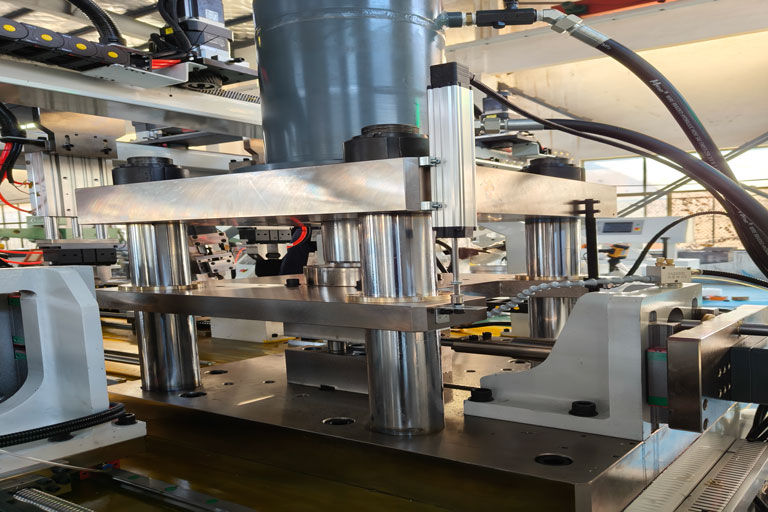

The hydraulic and pneumatic drive system of the automated production line is responsible for powering the movement and bending of pipes. Through connected hydraulic or pneumatic cylinders, it delivers the necessary force for precise pipe processing during bending operations.

Europe design structure with higher precision and speed. keep the machine used for a long time.

In the production of our double-head tube end forming machines and automated line equipment, we only use world-renowned, high-quality components: Japan Mitsubishi Servo, Germany Rexroth Hydraulics, France Schneider Electricals, Japan NOK Seal Rings, and CNC Controllers from Siemens or Japan Mitsubishi, among others.

Our automated production line offers high precision, flexible processing capabilities, and superior surface finishing, meeting the diverse material and product requirements to ensure high-quality finished products.

All the electrical parts in the cabinet are world-class brands, and the cabinet conforms to IP65.

Conform CE and UL standard

Specification

video

-

Contact

- WhatsApp

Whatsapp: +86-13901566802