Automatic CNC Bending Machine | MZ38CNC-3A-1S

Automatic CNC Bending Machine

● Dual Drive System: Combines servo and hydraulic drives for efficient and precise operation.

● Advanced Control: Centralized control for bending angle, feeding accuracy, and pipe rotation.

● Hydraulic Integration: Independent cylinders for clamping, guiding, and mandrel, ensuring synchronized and smooth performance.

● Bending Versatility: Supports both mandrel and non-mandrel bending for various pipe types.

● Ease of Use: Features jog and single-action modes for simple operation and maintenance.

● Wide Application: Ideal for industries like shipbuilding, boilers, chemicals, and automotive manufacturing.

An automatic CNC bending machine with a PLC or IPC manages Feeding (Y), rotating (B), and bending (C) in a complete automatic cycle.

Feeding (Y-Axis): Controlled by Servo motor.

Europe designs structures with higher precision and speed. keep the machine used for a long time.

Automatic CNC bending machines deliver high efficiency, precise control, and reduced labor costs by automating the entire bending process with minimal human intervention.

● Fully hydraulic movement on clamp die, pressure die, and mandrel.

● Available pipe material: steel, stainless, aluminum, titanium, and brass...

● Available pipe shapes: Round, Square, Rectangle, Oval, Solid Bar, and other profiles.

● Equipped with Japan Omron encoder, which ensures the accuracy and stability of bending.

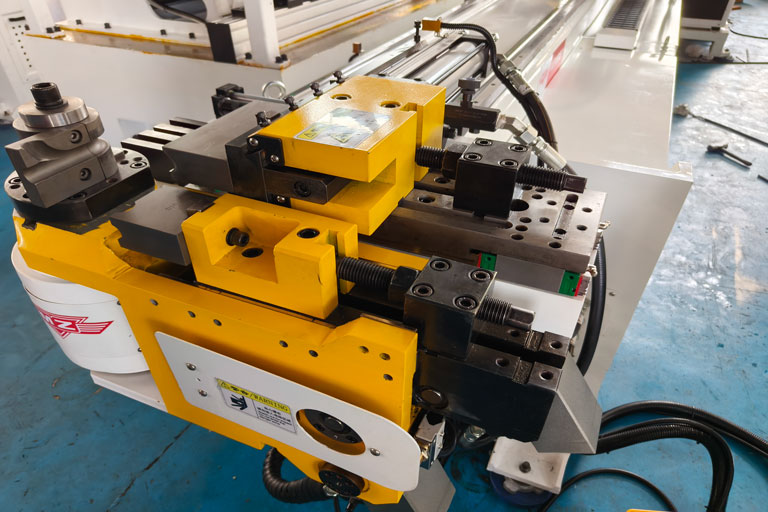

This component is a mold assembly on the automatic CNC bending machine, designed to accurately fix and position pipes. It enables precise bending of various pipe shapes and sizes, ensuring high accuracy and consistency in processing.

● Industry computer(IPC) touch screen 10inch/15inch offers easy access to automatic and manual operating modes.

● System diagnostics and multiple language capability.

● Fully hydraulic clamping on clamp die and pressure die.

● Equipped with an adjustable speed valve on the pressure die ensures the synchronization of bending.

● 3D Simulation Function and Drawing Transfer Function

● Wifi connection, and remote monitor

Specification

| NO. | Name | Unit | Parameters | Mark | |

| 1 | Max Processing Pipe Size | mm | Φ38×2t | Carbon steel | |

| Φ25×1.6t | Stainless steel | ||||

| 2 | Bending radius | mm | R180 | ||

| 3 | Max feeding length | mm | 2200 | Can be customized | |

| 4 | Feeding method | 1. Direct feeding

2. Clamping feeding |

Optional | ||

| 5 | Max bending angle | Degree | 190 | ||

| 6 | Using controller | PLC | |||

| 7 | Number of bends per fitting | 个 | 30 | ||

| 8 | Working speed | bending | Deg/sec | 100 | 8 |

| rotating | Deg/sec | 200 | |||

| feeding | Mm/sec | 1000 | |||

| 9 | accuracy | feeding | mm | ±0.1 | 9 |

| rotating | Degree | ±0.1 | |||

| bending | Degree | ±0.1 | |||

| 10 | Rotating servo motor | W | 750 | Mitsubishi | |

| 11 | Feeding servo motor | W | 1000 | Mitsubishi | |

| 12 | Bending servo motor | W | 5000 | Mitsubishi | |

| 13 | Data input mode | 1、Coordinate value(X、Y、Z)

2、Working value(Y、B、C) |

Optional | ||

| 14 | Hydraulic motor horsepower | Kw | 4 | ||

| 15 | Maximum pressure | MPa | 12 | adjustable | |

| 16 | Hydraulic system control | solenoid directional valve | Taiwan's Seven Oceans | ||

| 17 | Fuel tank capacity | L | 150 | ||

| 18 | Machine weight | Kg | 1500 | ||

| 19 | Machine size | cm | 78×95×131 | ||

video

-

Contact

- WhatsApp

Whatsapp: +86-13901566802