Automatic Pipe Bender | Customized Necking and Bending Line

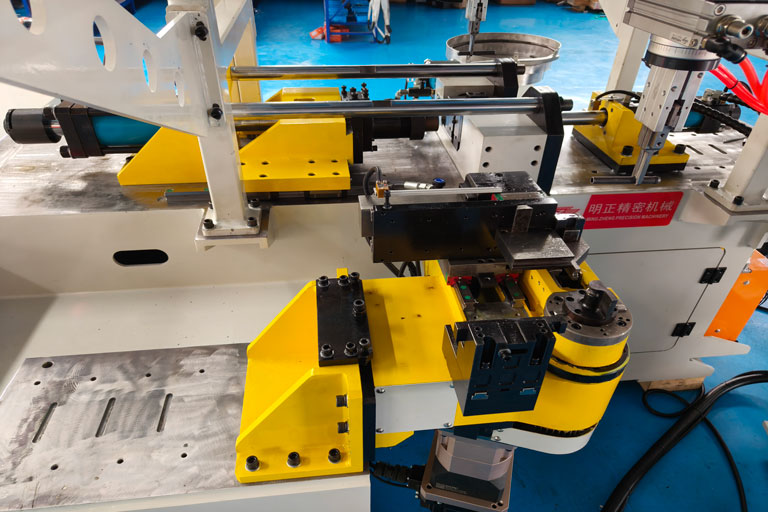

Automatic Pipe Bender

● Precision Engineering: Ensures accurate necking and bending for complex shapes.

● High Efficiency: Optimizes production speed and reduces downtime.

● Quality Components: Equipped with world-class parts for reliability and durability.

● Customizable Line: Tailored to meet specific industrial requirements.

● User-Friendly Interface: Easy operation with advanced CNC controls.

Automatic pipe bender with PLC or IPC which manages Feeding (Y), Rotate (B) & Bending (C) in a complete automatic cycle.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

We only use world-famous, popular-quality components in the production of our automatic pipe bender: Japan Mitsubishi Servo, Hydraulic Germany Rexroth, Electrical France Schneider, Seal ring Japan NOK, CNC Controller Siemens or Japan Mitsubishi, and so on.

The hydraulic and pneumatic drive system of the automatic pipe bender is responsible for powering the movement and bending of pipes. Through connected hydraulic or pneumatic cylinders, it delivers the necessary force for precise pipe processing during bending operations.

Ensure efficient and precise operation during the bending process to meet various processing needs.

● Industry computer(IPC) touch screen 10inch/15inch offers easy access to automatic and manual operating modes.

● System diagnostics and multiple language capability.

● Fully hydraulic clamping on clamp die and pressure die.

● Equipped with an adjustable speed valve on the pressure die ensures the synchronization of bending.

● 3D Simulation Function and Drawing Transfer Function

Wifi connection, and remote monitor

Our automatic pipe bender offers high precision, flexible processing capabilities, and superior surface finishing, meeting the diverse material and product requirements to ensure high-quality finished products.

-

Contact

- WhatsApp

Whatsapp: +86-13901566802