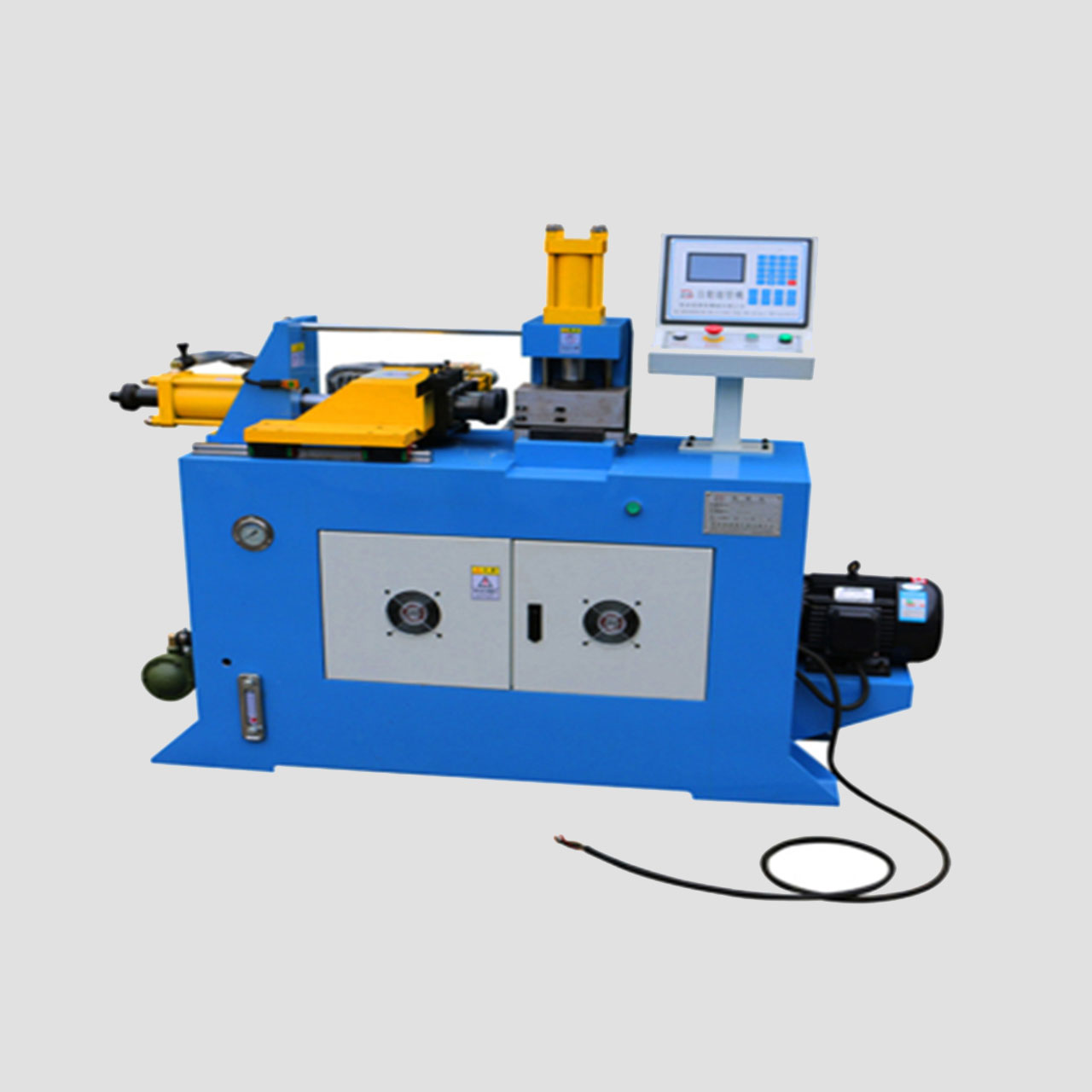

Two-Station Pipe End Forming Automatic Tube Bender Machine | TM-60

Two-Station Pipe End Forming Automatic Tube Bender Machine Introduction

1、Performance characteristics:

1) The two-station pipe end-forming automatic tube bender machine adopts a microcomputer-controlled power system, and the setting and operation are simple and easy to understand.

2) The mobile foot switch has three functions: automatic, emergency stop, and continuous after emergency stop, with high safety.

3) Equipped with various molding molds as needed, it can complete various pipe end shapes, such as single-end shrinkage, expansion, folding, and pier pipe fittings.

4) The mold replacement is simple and convenient for flexible production.

5) The hydraulic system adopts a centralized control circuit of oil pressure valves, which can extend the service life of various mechanical drive mechanism components. The multi-stage email design and a large-capacity water cooling circulation system ensure more stable machine operation.

2、Main technical parameters of automatic tube bender machine:

|

Parameter project |

EFM-60 |

| Maximum processing diameter and wall thickness (iron pipe) | Φ60mm*2.0mm |

| Maximum molding length | 100mm |

| Forming speed/second | 5-7S |

| Length of the formed workpiece | 1200 |

| Oil pump motor power | 5.5Kw |

| Rated working pressure | 10Mpa |

| Machine dimensions | 2150*850*1450mm |

| The gross weight of the machine | 1.5T |

| Name | Material or brand | Place of Origin |

| Bed frame | Steel plate welding (after tempering treatment) | Homemade |

| Platform panel | Ductile iron (QT500-7) | Homemade |

| Clamping seat "(with high steel performance, bending resistance, tensile resistance, and wear resistance) | Ductile iron (QT500-7) | Homemade |

| Large pallet "(with high steel performance, bending resistance, tensile resistance, and wear resistance) | Ductile iron (QT500-7) | Homemade |

| linear guide rail | PIM | Taiwan |

| Cylinder | Made with sealing rings imported from Italy | Homemade |

| Oil pump motor | Far East Weite (Junte) | Nantong |

| Microcomputer controller | Independent Research and Development | Homemade |

| power switch | Mingwei | Taiwan |

| Switch button | Tiande | Taiwan |

| proximity switch | Yangming | Taiwan |

| Intermediate relay | Tai'an | Taiwan |

| Contactor | Tai'an | Taiwan |

| thermal relay | Tai'an | Taiwan |

| solenoid directional valve | 7OCEAN | Taiwan |

| Stacked pressure maintaining valve | 7OCEAN | Taiwan |

| Oil pipe | 新科嘉 | Taiwan |

| manifold block | 油王油压 | Taiwan |

| Oil pump | YLC | Taiwan |

| Hydraulic system control (relief valve) | 7OCEAN | Taiwan |

| Hydraulic water cooler | HOTO | Taiwan |

3、 The usage conditions and power supply of the automatic tube bender machine:

1) Environmental temperature: 0-45 degrees. The machine operates smoothly, with precision and reliability;

2) Relative humidity: ≤ 90%. The machine operates smoothly, with precision and reliability;

3) Power supply: Power supply 380VAC (+/-10%), 50Hz (+/-1Hz);

4) Hydraulic oil: anti-wear hydraulic oil HM46 #;

5) Grounding method: The equipment must be reliably grounded;

-

Contact

- WhatsApp

Whatsapp: +86-13901566802