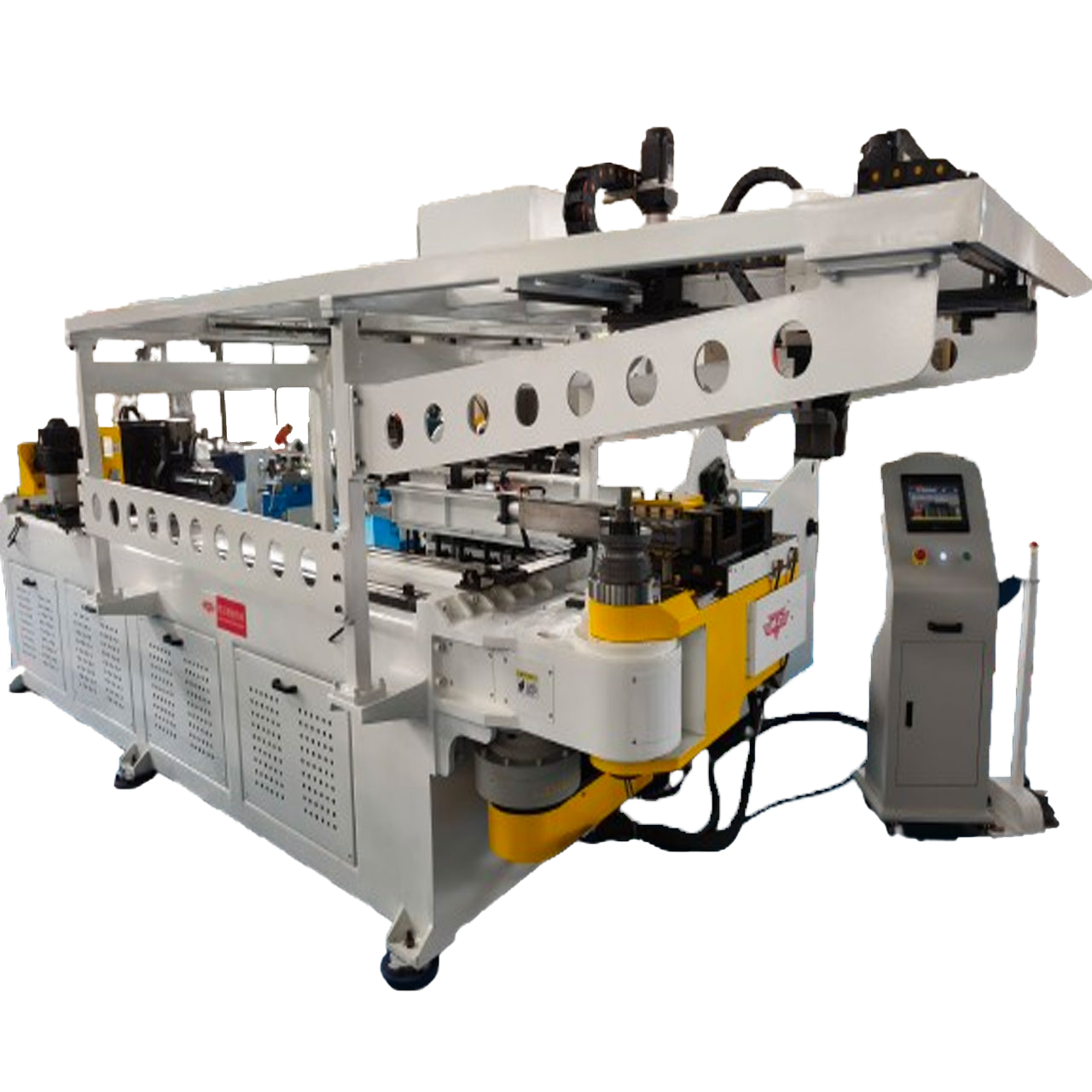

CNC Mandrel Pipe Bender | MZ75CNC Automation Line

CNC Mandrel Pipe Bender

● Servo-Hydraulic Drive: Ensures precise and stable bending operations.

● CNC Control: Allows for accurate angle, feeding, and rotation adjustments.

● Independent Hydraulic Cylinders: Controls clamping, guiding, mandrel, and bending for seamless coordination.

● Mandrel & Non-Mandrel Bending: Supports both bending methods for greater versatility.

● User-Friendly Operation: Features jog and single-action modes for easy use and maintenance.

● Wide Application: Ideal for shipbuilding, boilers, chemical, and automotive industries.

CNC mandrel pipe bender with PLC or IPC which manages Feeding (Y) , Rotate (B) & Bending (C) in a complete automatic cycle.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

Europe design structure with higher precision and speed. keep the machine used for a long time.

Our CNC mandrel pipe bender offers high precision, flexible processing capabilities, and superior surface finishing, meeting the diverse material and product requirements to ensure high-quality finished products.

● Cabinet all the electrical parts use world-class brands, and the cabinet conforms to IP65.

● Conform CE and UL standard

We only use world-famous, popular-quality components in the production of our CNC mandrel pipe bender: Japan Mitsubishi Servo, Hydraulic Germany Rexroth, Electrical France Schneider, Seal ring Japan NOK, CNC Controller Siemens or Japan Mitsubishi, and so on.

The hydraulic and pneumatic drive system of the CNC mandrel pipe bender is responsible for powering the movement and bending of pipes. Through connected hydraulic or pneumatic cylinders, it delivers the necessary force for precise pipe processing during bending operations.

Specification

| NO. | Name | Unit | Parameters | Mark | |

| 1 | Max Processing Pipe Size | mm | Φ75×3t | Carbon steel | |

| 2 | Max bending radius | mm | R300 | Customized | |

| 3 | Min bending radius | mm | According to OP | ||

| 4 | Max feeding length | mm | 3000 | Customized | |

| 5 | Feeding method | 1. Direct feeding

2. Clamping feeding |

optional | ||

| 6 | Max bending angle | Degree | 190 | ||

| 7 | Using controller | PLC | Customized | ||

| 8 | Number of bends per fitting | 个 | 30 | ||

| 9 | Working speed | bending | Deg/sec | 70 | adjustable |

| rotating | Deg/sec | 100 | adjustable | ||

| feeding | Mm/sec | 600 | adjustable | ||

| 10 | accuracy | feeding | mm | ±0.1 | |

| rotating | Degree | ±0.1 | |||

| bending | Degree | ±0.1 | |||

| 11 | Rotating servo motor | Kw | 1 | Mitsubishi | |

| 12 | Feeding servo motor | Kw | 2 | Mitsubishi | |

| 13 | Bending servo motor | Kw | 11 | Mitsubishi | |

| 14 | Data input mode | 1、Coordinate value(X、Y、Z)

2、Working value(Y、B、C) |

optional | ||

| 15 | Hydraulic motor horsepower | Kw | 7.5 | ||

| 16 | Maximum pressure | MPa | 14 | adjustable | |

| 17 | Hydraulic system control | solenoid directional valve | Taiwan Haitek | ||

| 18 | Fuel tank capacity | L | 250 | ||

| 19 | Machine weight | Kg | 4500 | ||

| 20 | Machine size | cm | 520×1350×1230 | ||

video

-

Contact

- WhatsApp

Whatsapp: +86-13901566802