Welcome to Mingzheng Precision Machinery

Types And Applications Of CNC Pipe Bending Machines

16 Apr

Discover the diverse types and applications of CNC pipe bending machines, revolutionizing precision in manufacturing across various industries.

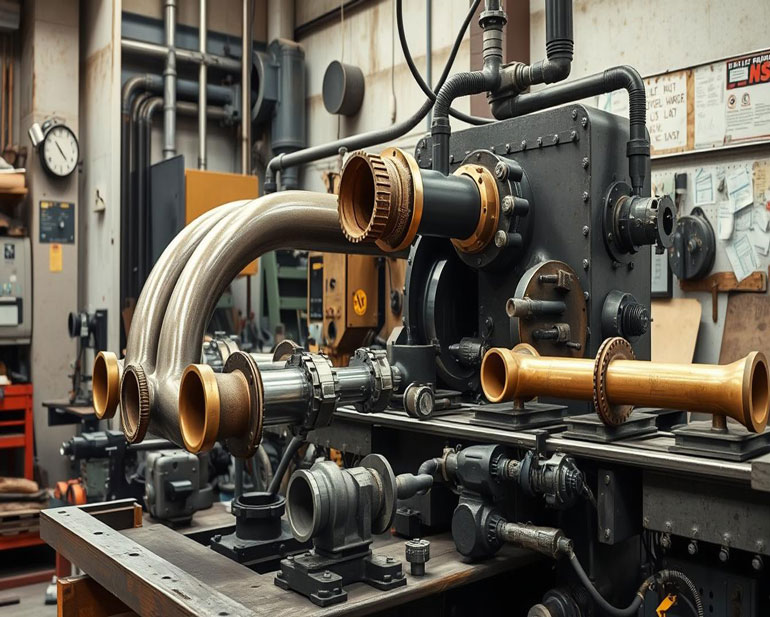

Types and applications of CNC pipe bending machines

CNC pipe bending machines are key in modern making. They shape metal for our cars and buildings. These machines are vital for precise work. The market for these tools may hit $1,344.60 million by 20341. They are very important in many fields, like making planes and cars.

New tube bending machines speed up work and cut mistakes1. They are great for making things like race car frames and medical gear. There are many kinds, like the strong Rotary Draw Bending Machine. It makes complex parts fast. And the Roll Bending Machine, which bends big arcs without messing up the material1.

Some machines are simple, like the Ram Bending Machine, for easy jobs. Others, like the Vector Tube Bending Machine, are for tough materials in planes and cars. These machines are very reliable. The Induction Bending Machine is good for the environment and works with big pipes. It shows our tools are ready for the future1.

These machines don't just work with heavy metals. They also shape things like hospital beds and pipes. They help make our living places safe and work better. They fit perfectly into making lines, offering special customization. This shows our dedication to quality and making our customers happy. CNC pipe bending machines are like the hands of creators in today's automated world.

Understanding CNC Pipe Bending Technology

CNC tube bending machines are key in today's fast-moving manufacturing world. They mix high-precision engineering with strong performance. This tech plays a huge role in enhancing various industries' production lines.

The Evolution of Metal Bending in Manufacturing

Metal bending has changed a lot from its early days. It was once done by hand, but now, tube bending tech uses automated systems. This results in better efficiency and accuracy. CNC machines are getting more popular because of increasing demand from those wanting to improve production.

Core Features of CNC Tube Bending Machines

● Precision: CNC machines are known for their exact angles and consistent production. This is very important in industries like aerospace and automotive.

● Versatility: They can work with tubes of different sizes. This includes small ones for medical tools and bigger ones for farm machines2.

● Cost Efficiency: Using CNC technology makes operations quicker and reduces labor costs. It also uses materials better and creates less waste2.

Operational Parameters in CNC Pipe Bending

CNC bending machines are made to handle different materials. This includes stainless steel, carbon steel, and aluminum. They can manage tubes up to several meters in diameter. This ensures they are flexible for many production needs23.

Also, CNC machines can now do complex bends in one go. This is true even for tubes that need tricky shaping. Before, this required many steps3.

CNC Pipe Bending Machine Varieties

With the growing need for detailed and efficient making, knowing about different CNC pipe bending machines is key. These tools play a big role in various pipe bending tasks. Every machine type is made for different requirements in industries.

Roll benders, known as angle rolls, are great for making tight circular bends. They're best for jobs that need non-stop circular shapes, like coils or spirals. On the other side, press brakes are right for making complex shapes. This makes them good for detailed architectural work where being precise is important.

Induction benders are top choices for bending big structural parts. They offer a mix of strength and accuracy without hurting the material. Rotary draw benders give amazing accuracy, needed for critical fields like aerospace and auto making. They are also used in making furniture and handrails where looks and accuracy are important.

| Machine Type | Applications | Benefits |

| Roll Bender | Coils, Spirals | Consistent circular forms |

| Press Brake | Architectural Details | Complex shapes with high precision |

| Induction Bender | Large Structural Components | Powerful yet precise bending |

| Rotary Draw Bender | Aerospace, Automotive, Furniture | Superior precision in critical applications |

Automated pipe bending tech has transformed industries by making things faster and cutting costs. CNC tube bending tools are better than manual ones in bending tubes. This improvement helps a lot in industries like heavy work and making goods for people.

The automation from CNC systems speeds up making things and improves quality. Fully automatic biaxial CNC pipe bending tools work faster than semi-automatic ones. They offer quickness and precision, raising productivity levels5.

The key role of CNC pipe bending in automation is keeping things exact and reliable. This exactness makes CNC bending very important in today's making processes. Mistakes or downtime can lead to big costs4.

The Role of CNC Machines in Automated Pipe Bending

CNC machines have changed how we bend pipes in making things. Using CNC pipe bending services and tube bending technology makes work precise and fast. These improvements help accuracy and speed in making things.

Accuracy and Precision in Automated Bending

CNC Mandrel Tube Benders create perfect bends without damage. This is vital for things that need to be very strong. Such as planes and cars6.

They are also key for making medical devices and plane parts very precise. Automation helps make top-quality products this way6.

Enhancing Manufacturing Efficiency with Automation

CNC pipe bending machines handle different sizes of tubes. They work in many areas like cars and buildings7. These machines work fast with little need for people6. Using AI and learning machines, they keep getting better at avoiding breakdowns6.

Changes in CNC machine technology are making things better across industries. This makes making things quicker and more precise6. CNC bending is leading the way in tech. It's setting up what making things will look like tomorrow.

Materials and Specifications in Precision Tube Bending Equipment

The materials chosen affect how well precision tube bending machines work. They can handle many materials, thanks to advanced tech. Stainless steel is often used for its strength and ability to resist rust. It helps make tubes flex without breaking and keeps them strong8. Chromoly steel is great for tough jobs due to its durability, making it a top pick for heavy-duty bending8.

Titanium is perfect for jobs needing to last a long time and stand up to heat and rust, even if it costs more. This makes it best for very special tasks8. Aluminum is chosen in fields that want things lighter and cooler. It's perfect for flying or driving machines because it's light and loses heat fast8.

Talking about what machines can do, they can work with all sorts of tube sizes, thicknesses, and how sharp bends are. This lets makers make things just right for each customer. Draw bending lets us bend big, stiff tubes without messing them up. A tool helps keep the tube's shape while it bends9.

Different bending ways meet different needs. Roll bending makes gentle curves and uses three rollers to get the curve just right9. How hard you press the rollers can change how sharp the bend is. This is key for making complicated shapes.

| Material | Properties | Preferred Application |

| Stainless Steel | Ductile, Corrosion Resistant | Hydroform Tube Bending |

| Chromoly Steel | Tough, High Strength | CNC Tube Bending Operations |

| Titanium | Durable, Corrosion and Temperature Resistant | High-Performance Bending |

| Aluminum | Lightweight, High Thermal Conductivity | Aerospace and Automotive |

Matching these materials with top-notch machines ensures great results. It lets us work in lots of fields. Our goal is to offer technology that's not just advanced but also fits many needs.

Industries and Applications for CNC Pipe Bending

CNC pipe bending machines are vital for efficiency and precision in many industries today. This industry keeps evolving with advanced technology for different needs.

CNC Bending in Aerospace and Automotive Sectors

The aerospace and automotive industries depend a lot on CNC pipe bending. Machines like the Comco KB Series and the KBB-70 are crucial for making parts like exhaust systems and aircraft frames. They can bend tightly with minimum space, meeting the high standards of these sectors10.

These CNC technologies also cut manual work by 50-60%. This makes things safer and saves on labor costs. It helps in making production more economical11.

Diverse Uses of CNC Bending in Construction and Architecture

In construction and architecture, CNC pipe bending machines play a big role. They help create custom parts and maintain building strength by shaping materials precisely. These machines are getting more popular, expected to grow 2.80% annually till 2031. This shows how much they are needed for big construction projects12.

This need is also reflected in the production speed, reaching 200-300 bends an hour. This speed helps meet urgent needs in architecture efficiently11.

| Machine Model | Industry Application | Feature | Impact on Production |

| Comco TMS Electric CNC | Aerospace | Quick-change tooling | Setup time under 10 mins10 |

| KBB-70 Booster Bender | Automotive | Compact bend head for 1D bends | Minimizes clamp length10 |

| Comco KB Series | Construction | Servo-driven accuracy | Decreases material wastage by 15-20%11 |

| TWS Series CNC Benders | Public Railway Construction | Automated loaders/unloaders | Reduces cycle times, increases output10 |

These CNC pipe bending innovations boost production and lower costs. Including such machinery in our work shows our dedication to quality and efficiency. It means we always give our clients the best solutions for their needs.

Specialized Bending Machine Capabilities

In the world of making things, CNC bending machines are changing the game. They make metal shaping super precise and efficient. This is really important in making cars, planes, and lots of other stuff.

Assessing Performance Metrics of CNC Benders

It's super important to check how well CNC pipe benders are doing. They need to be very exact in making products. These machines are special because they use a servo motor. This lets them control bending operations very closely13. They can bend different materials like steel and aluminum. This makes them useful in many types of manufacturing13. By being so precise, they save materials and boost production14.

Customization Options in CNC Pipe Benders

Customizing CNC pipe benders helps with creativity and flexibility. For example, the EMS TB series offers different models for many bending jobs14. They can do a lot of different bends because of special kits and roller presses13. This makes them great for unique tasks in shipbuilding, aerospace, and art15.

New technology in these machines improves what they can do. This helps meet production needs more accurately. The advancement of these machines shows they are worth the investment. They make manufacturing much better.

Choosing the Right CNC Pipe Bending Services

Choosing the right CNC pipe bending service is key. You must look at many aspects to ensure high accuracy and performance. Our method focuses on what matters most to our clients for the best results.

Evaluating Service Providers for CNC Bending Projects

Finding a good provider means checking their machine skills, work speed, and rule following. Important points to see include:

● The kind of power used, like hydraulic machines, affects bend precision and types16.

● The ability to use different tool sets impacts how well multiple bends are made16.

● Getting regular help from the provider avoids long stops and keeps quality high16.

● Choosing those with up-to-date CNC tech results in more accurate and faster work16.

Cost-effective Solutions and Production Scale Considerations

It's important to find a balance between cost and what you need produced today. To do this, look at:

● How much the machine can make and how it uses energy affects cost1617.

● Thinking about the upfront cost vs. long-term savings, especially with high-quality machines is key17.

● How much waste and material use efficiency matter a lot for keeping costs down17.

Finding a good CNC pipe bending service is more than just the tech stuff. It's about getting a partner that fits your project needs and goals for a future of success. Being able to handle various projects well and use resources wisely is vital.

| Feature | Benefit |

| Advanced CNC technology | Brings you high precision and repeated accuracy in bends |

| Multiple tool stacks | Allows handling many bend radii, adding flexibility |

| Robust maintenance support | Leads to fewer stops and steady work |

| Energy efficient operations | Lowers work costs and is better for the planet |

Conclusion

Reflecting on this article shows the importance of CNC pipe bending machines in the industry. They make high-precision bends, fitting complex shapes with great control18. This allows use across different materials and thicknesses. It impacts many applications, from metal sheets to tubes18. The machines also provide efficiency with their multi-axis bending for intricate designs18 and diverse tooling options18.

We found that these machines deeply impact key sectors. For example, the automotive and aerospace industries depend on them for meeting strict standards. CNC benders can bend pipes up to 360 degrees swiftly and accurately1819. This is a big improvement over manual or hydraulic methods19. Electric tube benders, offering up to 180-degree bends, push this further19. They show how technology is setting new efficiency standards.

Looking ahead, CNC pipe bending will bring even higher precision. Machines will handle rounds up to 5.9" and have advanced features like 12 turret stations20. This shows our commitment to top-quality manufacturing solutions. We aim to meet future market demands with automated precision. Our goal is always to deliver reliability and expertise in CNC pipe bending.

FAQ

What are the different types of CNC pipe bending machines?

There are a few main types. Roll benders make sharp circular shapes. Press brakes can create complex forms. Induction benders work great for big parts. Rotary draw benders are known for their detail. Each type fits different industry needs.

How has metal-bending technology evolved within manufacturing?

Metal bending has come a long way. It went from basic hand tools to complex CNC technology. This growth focuses on being exact and automated. This way, pressure is always right, and shaping is uniform. These are key for stopping metal fatigue and keeping structures safe.

What are the core features of CNC tube bending machines?

The key features are many. They can control bend angles and sizes very precisely. They can make complex, detailed designs. They're programmed to do tasks the same way over and over. And, they can work with many materials and sizes.

What are the critical operational parameters in CNC pipe bending?

Some vital parameters are big. They include the pipe's outer size, wall thickness, and bend radius. The material's makeup also matters. Machines must be set right to work with these factors. This helps achieve the exact bends wanted.

How do CNC machines enhance accuracy and precision in automated pipe bending?

CNC machines use smart programming and precise controls. This cuts down on mistakes and makes sure things are done the same way every time. It leads to a better and more efficient making process, and the end products are of higher quality.

Why are precision tube bending equipment and their specifications important?

It's crucial because equipment must match material needs such as bendability, strength, and size. The right equipment specs make sure materials stay top-notch during the bending.

In which industries are CNC pipe bending machines most commonly used?

Many industries need these machines. For example, the aerospace, car-making, and building sectors. They're also used in making parts for HVAC, vehicle exhausts and frames, and things for buildings.

What capabilities do specialized CNC bending machines offer?

These machines can do a lot. They can make detailed shapes for cars or do big bends for ships. The option to add kits that do many things makes them even better for different jobs.

How do you evaluate service providers for CNC pipe bending projects?

When picking a provider, look at their knowledge, tech, and if they are cost-effective. Also, check their speed, how much they can make, and if their machines fit with the materials. This makes sure they work well and efficiently.

What considerations should be taken into account for cost-effective CNC pipe bending solutions?

Think about the project’s complexity, how big the order is, how fast it needs to be done, and the materials used. Choosing the right provider matching these aspects can save money and make the process smoother.