Customized Automatic Loading and Unloading Double Head Pipe Expansion Machine

Automatic Loading and Unloading Double Head Pipe Expansion Machine Introduction

* High Automation: Fully automated loading and unloading significantly reduce manual intervention and improve production efficiency.

* Simultaneous Processing: The dual-head design processes both ends of the pipe simultaneously, enhancing production speed.

* Precision and Consistency: Intelligent control and precise mechanical systems ensure consistent quality for every workpiece.

* Adaptability: Supports various pipe specifications and materials to meet diverse production requirements.

* Energy Efficiency: Optimized drive and cooling systems minimize energy consumption and material waste.

* Automatic Loading Mechanism: Equipped with a servo-controlled manipulator or conveyor system that transfers pipes from the material hopper to the processing area, saving labor and improving efficiency.

* Automatic Unloading Mechanism: The finished pipes are seamlessly transferred to the collection area, ensuring smooth workflow and convenient operation.

* Material Hopper Management: Features an intelligent material hopper capable of storing and identifying various pipe specifications, ensuring stable and continuous loading and unloading.

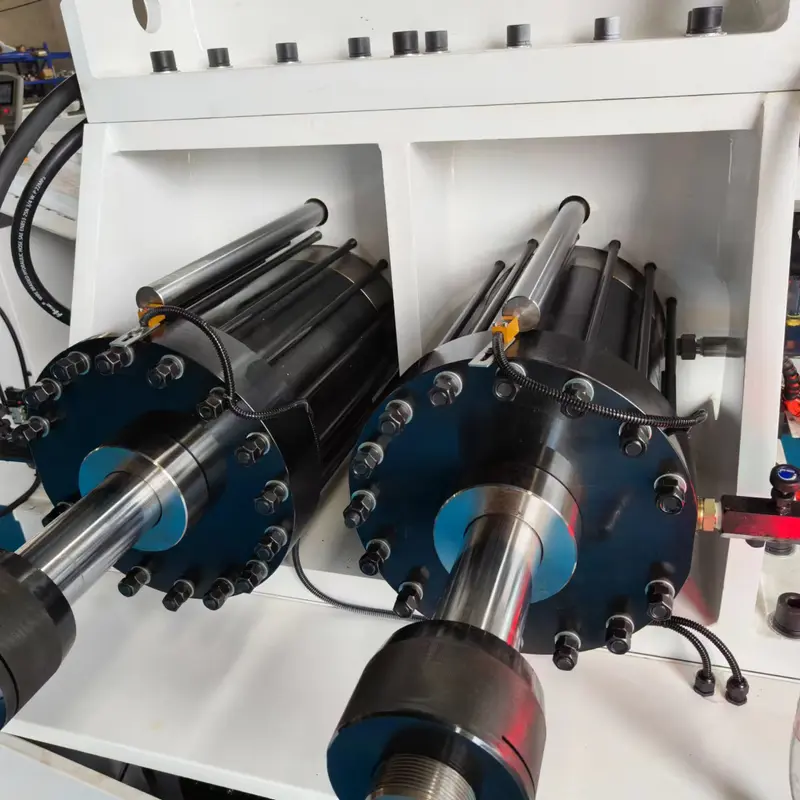

* Expansion Head Structure: Utilizes high-strength alloy expansion heads for simultaneous processing of both pipe ends, maximizing efficiency.

* Precision Expansion: Equipped with a precision guiding system to ensure uniform dimensions and angles for each expansion process.

* Versatility: Pipe expansion machine supports quick mold change of different diameters and wall thicknesses.

-

Contact

- WhatsApp

Whatsapp: +86-13901566802