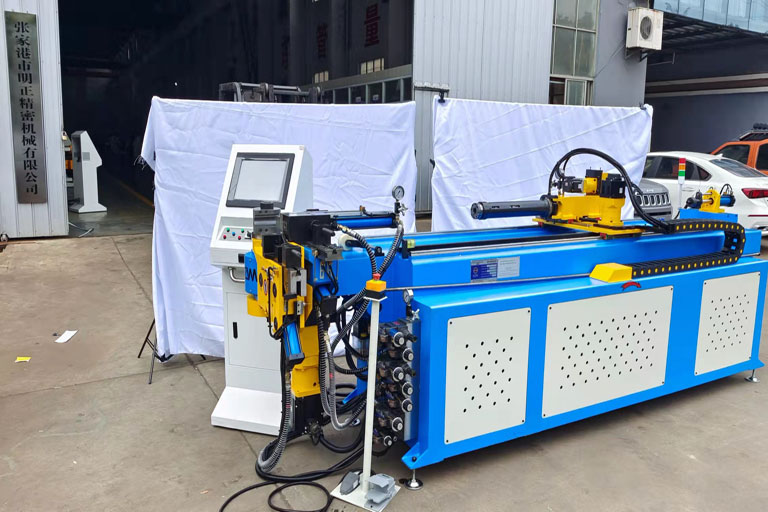

Industrial Pipe Bending Machine | MZ50CNC-3A-1S

Industrial Pipe Bending Machine

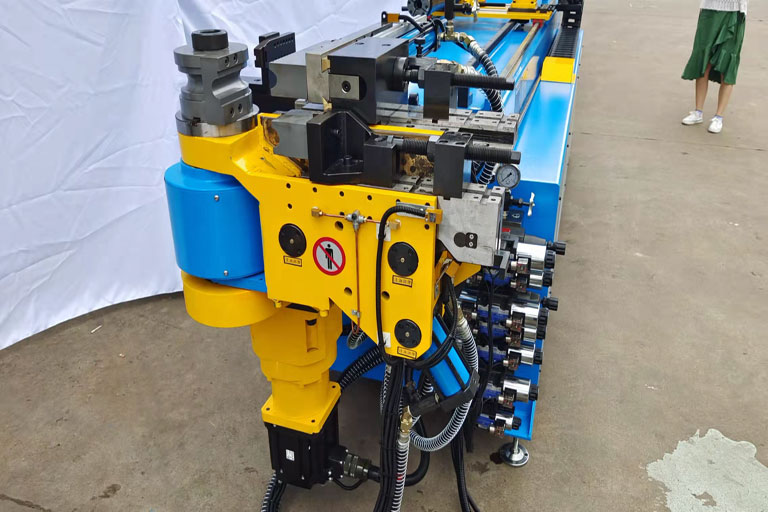

● Dual-Drive System: Combines servo and hydraulic drives for efficient, precise operation.

● Advanced Control: Centralized electrical control of bending angle, feeding accuracy, and tube rotation.

● Hydraulic System: Independent hydraulic cylinders for clamping, guiding, mandrel, and other key functions, ensuring smooth, synchronized movement.

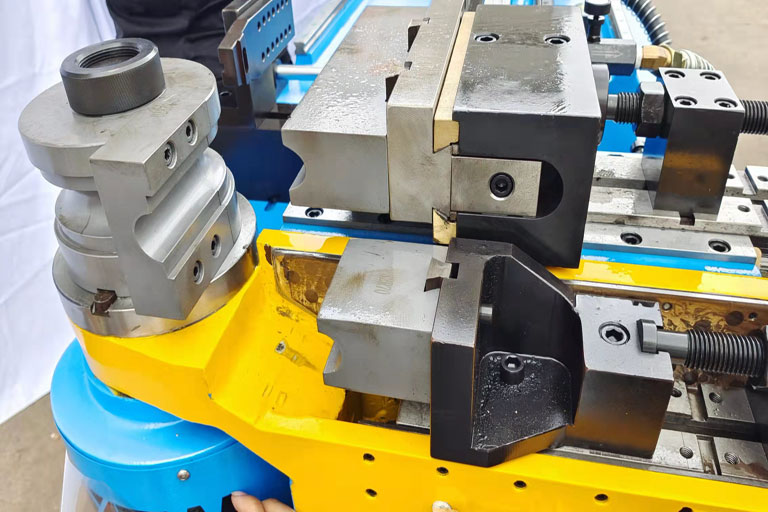

● Bending Versatility: Supports both mandrel and non-mandrel bending for different pipe types.

● Easy Operation: Offers jog and single-action modes for simple operation and maintenance.

● Wide Application: Used in shipbuilding, boilers, chemicals, and automotive manufacturing industries.

Industrial pipe bending machine with PLC or IPC that manages Feeding (Y), Rotation (B), and bending (C) in a complete automatic cycle.

Fully hydraulic movement on clamp die, pressure die, and mandrel.

Available pipe material: steel, stainless, aluminum, titanium, and brass...

Available pipe shapes: Round, Square, Rectangle, Oval, Solid Bar, and other profiles...

Equipped with a Japan Omron encoder ensures the accuracy and stability of bending.

Only use world-famous popular quality components in the production of our industrial pipe bending machine: Japan Mitsubishi Servo, Hydraulic Germany Rexroth, Electrical France Schneider, Seal ring Japan NOK, CNC Controller Siemens or Japan Mitsubishi, and so on.

L'Europe conçoit des structures d'une plus grande précision et d'une plus grande rapidité, ce qui permet d'utiliser la machine pendant une longue période.

The main function of the system is to control the hydraulic fluid distribution, precisely adjusting the bending angle and degree to enable efficient pipe processing.

The main function is to securely hold the pipe during bending, ensuring stability and precision, with adjustable fixtures and molds to accommodate different pipe sizes and shapes for efficient processing.

Spécifications

| NON. | Nom | Unité | Paramètres | Marque | |

| 1 | Taille maximale du tuyau de traitement | mm | Φ50×3t | Acier au carbone | |

| 2 | Rayon de courbure | mm | R180 | ||

| 3 | Longueur maximale d'alimentation | mm | 2500 | Peut être personnalisé | |

| 4 | Méthode d'alimentation | 1. Alimentation directe

2. Alimentation par serrage |

En option | ||

| 5 | Angle de flexion maximal | Diplôme | 190 | ||

| 6 | Utilisation du contrôleur | PLC | |||

| 7 | Nombre de coudes par raccord | 个 | 30 | ||

| 8 | Vitesse de travail | flexion | Deg/sec | 80 | 8 |

| tournante | Deg/sec | 120 | |||

| l'alimentation | Mm/sec | 800 | |||

| 9 | précision | l'alimentation | mm | ±0.1 | 9 |

| tournante | Diplôme | ±0.1 | |||

| flexion | Diplôme | ±0.1 | |||

| 10 | Servomoteur rotatif | W | 750 | Mitsubishi | |

| 11 | Servomoteur d'alimentation | W | 1500 | Mitsubishi | |

| 12 | Servomoteur de cintrage | W | 7000 | Mitsubishi | |

| 13 | Mode d'entrée des données | 1、Coordonnée(X、Y、Z)

2、Working value(Y、B、C) |

En option | ||

| 14 | Puissance du moteur hydraulique | Kw | 5.5 | ||

| 15 | Pression maximale | MPa | 14 | réglable | |

| 16 | Contrôle du système hydraulique | valve directionnelle solénoïde | Les sept océans de Taïwan | ||

| 17 | Capacité du réservoir de carburant | L | 180 | ||

| 18 | Poids de la machine | Kg | 2500 | ||

| 19 | Taille de la machine | cm | 480×110×130 | ||

vidéo

-

Contact

- WhatsApp

Whatsapp : +86-13901566802

- Courriel