Welcome to Mingzheng Precision Machinery

What Types Of Pipes Can Be Bent By The Pipe Bending Machine?

11 Apr

Discover the variety of pipes adjustable with a pipe bending machine, including steel, copper, and PVC for various industrial needs.

What types of pipes can be bent by the pipe bending machine?

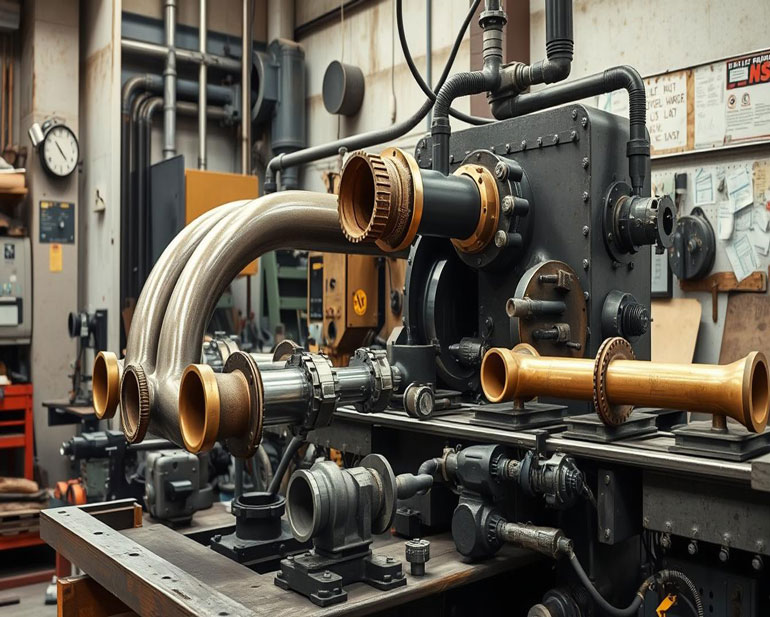

In manufacturing and construction, the pipe bending machine is key. It helps achieve design and function flow. The main question is how different types of pipes fit the pipe bending capabilities of today's machines. Experts use their skills to match the technique with the right pipe. This could be steel for buildings or aluminum for lighter uses. There are over ten bending techniques used today, each for specific needs1.

Rotary draw bending is very popular, especially for custom automotive exhausts. This technique is a top choice in the car and motorcycle world12. For pipes that must keep their shape, like in aerospace or gym gear, mandrel tube bending is best. It keeps the pipe's integrity during intense reshaping1.

The heat induction bending process bends thick tubes gracefully while saving energy1. On the flip side, ram bending is simpler and cheaper, good for less precise shapes1. Modern CNC pipe bending machines bring precision and consistency. They're great for complex bends needed in cars or for bending copper pipes in plumbing2.

The success of a bend relies on budget, precision, and material size. These factors help choose the right machine for the job1. With so many options, the real question is how well the bend can be done.

Understanding Pipe Bending Techniques and Applications

In metal fabrication, knowing different pipe bending methods helps improve the making of items and their quality. Each type of bending has its special advantages for certain jobs. It shows why picking the correct method is vital for your project.

The Essentials of Press and Rotary Draw Bending

Press bending and Rotary Draw Bending are key in shaping pipes. Press bending is simple and saves money. It is best when exactness isn't needed. Yet, this way can limit design choices and risk pipe damage if done wrong3. On the flip side, Rotary Draw Bending is great for precise bends. It's used for things like car roll cages and furniture4. This method gives consistent, high-quality curves but costs more to set up.

Compression Bending and Roll Bending Explained

Compression Bending is quick and economical for simple jobs, such as electrical conduits4. It's limited to certain pipe sizes and shapes, though. Roll Bending, however, can handle many sizes and shapes. It's ideal for creating complex designs found in architecture and art. This ability to curve pipes in many directions helps make unique structures3.

Mandrel Tube Bending: Preserving Pipe Integrity

Mandrel Tube Bending is crucial for keeping pipes' shape and size during bending. Using a mandrel stops the pipe from collapsing and keeps bends even3. This method is key for making important parts like those in planes and cars, where every detail must be perfect.

Heat Induction and Sand Packing: Navigating High-Temperature Bending

Heat Induction Bending and Sand Packing are important for bending pipes under high heat, used in big industries like petrochemical and construction. Heating the pipe before bending lets you shape thick pipes more easily, keeping the metal's quality3. Sand packing helps support the pipe while bending, reducing warping and keeping sizes accurate4. These techniques are best for making big bends needed in large projects.

| Technique | Application | Industries |

| Rotary Draw Bending | Precision bends for automotive and furniture | Manufacturing, Automotive |

| Press Bending | Cost-effective bends for non-critical parts | Construction, Industrial |

| Compression Bending | Simple bends, e.g., electrical conduits | Electrical, Construction |

| Roll Bending | Large, complex structures | Architecture, Art |

| Mandrel Tube Bending | Structural integrity for critical components | Aerospace, Automotive |

| Heat Induction Bending | Thick-walled pipes for industrial uses | Petrochemical, Construction |

What Types of Pipes Can Be Bent by the Pipe Bending Machine?

Today, knowing about pipe bending machines is key for those making or designing products5. These machines shape various pipe bending materials into needed forms. This supports many industrial uses.

Different pipe bending types include compression, rotary draw, roll bending, and mandrel bending5. Each method works well with certain materials and bending needs. For example, tough stainless steel often uses rotary draw bending for precise bends. Softer materials like copper are easier to bend with roll bending6.

The industrial pipe bending process looks at wall thickness and diameter. These factors help choose the best bending method6. Knowing these methods well is important. It helps pick the right equipment and keeps the pipe strong after bending.

● Rotary Draw Bending: Perfect for precise bends in the auto and aerospace fields7.

● Compression Bending: Great for simple tasks like bending electrical pipes, offering speed and cost savings5.

● Roll Bending: This works for bending big metal sheets and pipes used in shipbuilding and big builds7.

● Mandrel Tube Bending: Puts a mandrel inside the tube to keep its shape and strength, vital for high-performance uses like racing cars and planes7.

Each method helps the pipe-bending materials stay strong and functional after bending7. In places like the petrochemical field, mandrel bending is the top choice. It keeps the inside surface smooth, which is needed for fluids to flow well.

Working with an expert in pipe bending types makes a project more successful6. Their deep knowledge is crucial for meeting specific industry standards in industrial pipe bending.

The right pipe and method choice greatly affects project results. It underlines the need to make smart choices early in project planning. Different jobs, like detailed aerospace parts or large architectural shapes, show why knowing modern pipe bending machines is basic5.

Factors Influencing the Pipe Bending Process

In today's world, knowing what affects pipe bending is key. These factors decide8 how well and where the bent pipes can be used. Key points include pipe type, thickness, bend shape, and choosing the right bending method for different pipes.

Considering Pipe Material and Wall Thickness

First, look at the pipe's material and its thickness. Pipes are made from steel, aluminum8, and copper, each with unique bending abilities. Steel pipes, especially thick ones, need strong machines to bend them without cracking.

Also, the thickness of a pipe is crucial. It affects which bending method to use and keeps the pipe's shape after bending. Thicker pipes are stronger but need better bending tech to maintain their form.

Impact of Bend Radius on Pipe Bending

The bend radius is crucial in pipe bending. It's about how tight the bend will be and is based on the pipe's size. The right bend radius makes sure the pipe works well and stays in shape, especially when it’s important for moving fluids properly.

Keeping an eye on the bend radius is important. Too tight of a bend can break the outer part of the pipe. This risks the whole bending task and the end product's use.

Assessing the Pipe Size and Shape Requirements

Different jobs may need different pipe sizes and shapes. It's important to match these needs with what the bending machine can do. For example, machines for steel tubes work best with thin walls and tight bends. They’re great for detailed work where being precise matters a lot.

But, bigger or more unusual pipe shapes might require stronger bending methods. Like mandrel tube bending, used often in making car exhaust pipes. Starting with a good plan for the bend makes sure the making goes smoothly and the final pipes are top-notch.

To bend pipes well, mixing knowledge on material, thickness, bend shape, size, and form is critical. Fitting these with the project goals and what the bender can do leads to the best bends. It helps meet set industry standards, too.

Our focus on getting these factors right shows our promise to give precise and quality pipe bending options. We want to fulfill the wide needs of our clients' projects.

Critical Advantages and Limitations of Pipe Bending Types

Looking at pipe bending means examining all the pros and cons. We see how speed, cost, precision, and use in industries balance out.

Cost and Speed: Weighing the Benefits

The cost and speed of bending pipes have their own trade-offs. For simple projects, compression bending is cheap and easy but slow9. On the other hand, rotary draw bending is faster and more precise, but it costs more. This makes it great for jobs that need quick and accurate bends9.

Precision and Versatility Across Industries

Choosing a pipe bending method often depends on how precise it needs to be. Rotary draw bending is perfect for jobs requiring precise measurements, like car parts9. This method works with many materials, which is why lots of industries prefer it10.

Risks and Precision in Pipe Bending Methods

Choosing a bending method affects speed, cost, and risks. Mandrel tube bending is efficient with less material harm but needs a big investment in tools9. Roll bending costs less and works for pipes and sheet metal, but it might weaken the workpiece9.

In short, understanding pipe bending methods means looking at their costs, speed, precision, and risks. Picking the right method helps make manufacturing better. Keeping up with these methods is key to good decisions in making things.

Conclusion

In our talk about bending pipes, we've looked at why it's key in making things better and finding the best ways to bend. There are many ways to bend pipes, each good for different needs. This shows that bending is not just pushing on metal. It's using smart design, knowing the metal's limits, and making it fit various jobs1112.

Choosing the right tools and ways to bend pipes is important. We might use hydraulic benders or others that are strong and precise. These tools help us make things with care1312. They are vital for big industries like oil and car making. So, we think about many things to make sure our bent pipes are strong and reliable1312.

To help people understand this important skill, looking at the different ways to bend tubes is very helpful. As we finish talking about this, it's clear that picking the right bending method is very important. It matters a lot for making things well and ensuring they last11.

FAQ

What types of pipes can be bent by the pipe bending machine?

Pipe bending machines can bend many pipes like steel, copper, aluminum, and PVC. These pipes are used in making things, building, and fixing pipes. Each pipe type needs the right settings based on its material, thickness, and size. This ensures the pipe bends right without damage.

What are the essentials of press and rotary draw bending?

Press bending is fast and cheap. It's good when you don't need perfect bends. On the other hand, rotary draw bending makes precise bends. It's used for things that need careful bending, like roll cages. Your project's needs will tell you which method is better.

What are compression bending and roll bending?

Compression bending is old and good for easy jobs like making electric conduits. It's quick with a simple setup but not very flexible. Roll bending can make curves in many directions. It's used for complex shapes but is slower and needs testing to get right.

What is mandrel tube bending, and how does it preserve pipe integrity?

Mandrel tube bending helps keep hollow tubes in shape when bending. A solid bar called a mandrel is put inside the tube to stop it from collapsing. This is great for making exhaust pipes and gym equipment. It makes sure the tube stays strong.

How do heat induction and sand packing aid in high-temperature pipe bending?

Heat induction bending softens metal pipes with heat to bend them more easily. This often uses a hot coil. Sand packing fills pipes with sand to keep their shape while heating and bending. These methods help bend thick pipes and are important in many big industries.

Which factors influence the pipe bending process?

The bending of pipes is affected by the pipe's material, thickness, and size. What bend you want also matters. These things change how easy a pipe is to bend and keep strong. They also decide which bending way or machine you should use.

How does the cost and speed of bending vary between different pipe bending types?

Some bending methods are cheap and quick but might not bend perfectly. Others, like rotary draw and mandrel bending, are very accurate. They cost more and take more time to set up. Choosing a method involves thinking about money, how fast you need it, and how precise.

How do precision and versatility impact industry-specific applications of pipe bending?

Different jobs need different levels of bending precision. In car and airplane making, it's very important to bend accurately. That's why they often use rotary draw bending. Other times, saving money might be more important than perfect bends. What you need the bend for helps decide which way to bend.

What are the risks and precision considerations in pipe bending methods?

Each way of bending pipes has its own risks. Press bending can be fast but might not be very accurate. Rotary draw bending makes even bends. But with roll bending, there's a chance of hurting the tube if it's bent too much. Mandrel bending makes good bends but takes longer and costs more. It's important to think about these things when picking a bending method.