Pipe Folding Machine | MZ90CNC-3A-1S

Pipe Folding Machine

● High Precision: Delivers accurate and consistent folds with minimal deformation.

● Material Compatibility: Supports stainless steel, aluminum, copper, and more.

● Customizable Folding: Adjustable angles and pipe sizes for versatile applications.

● User-Friendly Control: Intuitive touch-screen interface for easy operation.

● Durable and Reliable: Built with heavy-duty materials for long-lasting performance.

● Safety Features: Includes automatic shutdown, overload protection, and secure clamping.

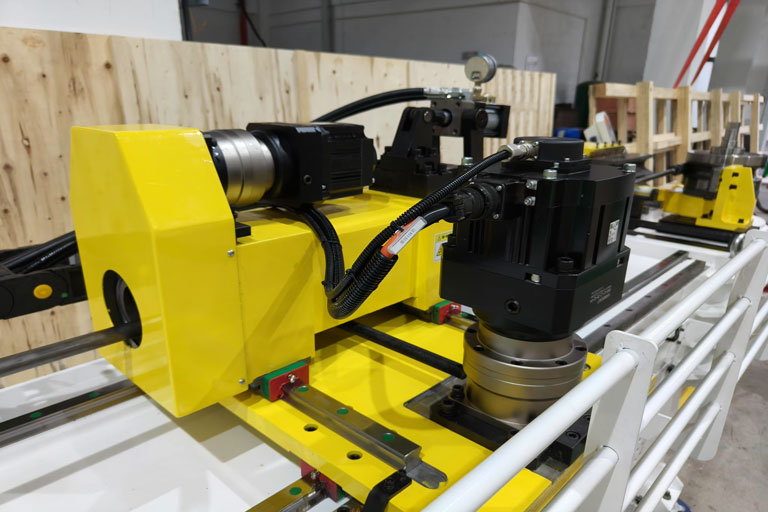

The hydraulic and pneumatic drive system of the pipe folding machine is responsible for powering the movement and bending of pipes. Through connected hydraulic or pneumatic cylinders, it delivers the necessary force for precise pipe processing during bending operations.

Pipe folding machine with PLC or IPC which manages Feeding (Y) ,Rotate (B) & Bending (C) in a complete automatic cycle.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis ): Controlled by Servo motor.

Europe design structure with higher precision and speed. keep the machine used for a long time.

● Cabinet all the electrical parts use world-class brands, and the cabinet conforms to IP65.

● Conform CE and UL standard

● Industry computer(IPC) touch screen 10inch/15inch offers easy access to automatic and manual operating modes.

● System diagnostics and multiple language capability.

● Fully hydraulic clamping on clamp die and pressure die.

● Equipped with an adjustable speed valve on the pressure die ensures the synchronization of bending.

● 3D Simulation Function and Drawing Transfer Function

Wifi connection, and remote monitor

Our pipe folding machine offers high precision, flexible processing capabilities, and superior surface finishing, meeting the diverse material and product requirements to ensure high-quality finished products.

Specification

| NO. | Name | Unit | Parameters | Mark | |

| 1 | Max Processing Pipe Size | mm | Φ89×6t | Carbon steel | |

| 2 | Max Bending radius | mm | R300 | ||

| 3 | Min Bending radius | mm | According to OD | ||

| 4 | Max feeding length | mm | 3000 | Customized | |

| 5 | Feeding method | 1. Direct feeding

2. Clamping feeding |

optional | ||

| 6 | Max bending angle | Degree | 190 | ||

| 7 | Using controller | PLC | optional | ||

| 8 | Number of bends per fitting | 30 | |||

| 9 | Working speed | bending | Deg/sec | 40 | adjustable |

| rotating | Deg/sec | 160 | adjustable | ||

| feeding | Mm/sec | 550 | adjustable | ||

| 10 | accuracy | feeding | mm | ±0.1 | |

| rotating | Degree | ±0.1 | |||

| bending | Degree | ±0.1 | |||

| 11 | Rotating servo motor | Kw | 1.5 | Japan Mitsubishi | |

| 12 | Feeding servo motor | Kw | 2 | Japan Mitsubishi | |

| 13 | Data input mode | 1、Coordinate value(X、Y、Z)

2、Working value(Y、B、C) |

optional | ||

| 14 | Hydraulic motor horsepower | Kw | 11 | ||

| 15 | Maximum pressure | MPa | 14 | adjustable | |

| 16 | Hydraulic system control | solenoid directional valve | Taiwan's Seven Oceans | ||

| 17 | Fuel tank capacity | L | 450 | ||

| 18 | Machine weight | Kg | 约5000 | ||

| 19 | Machine size | mm | 5500×1350×1360 | ||

video

-

Contact

- WhatsApp

Whatsapp: +86-13901566802