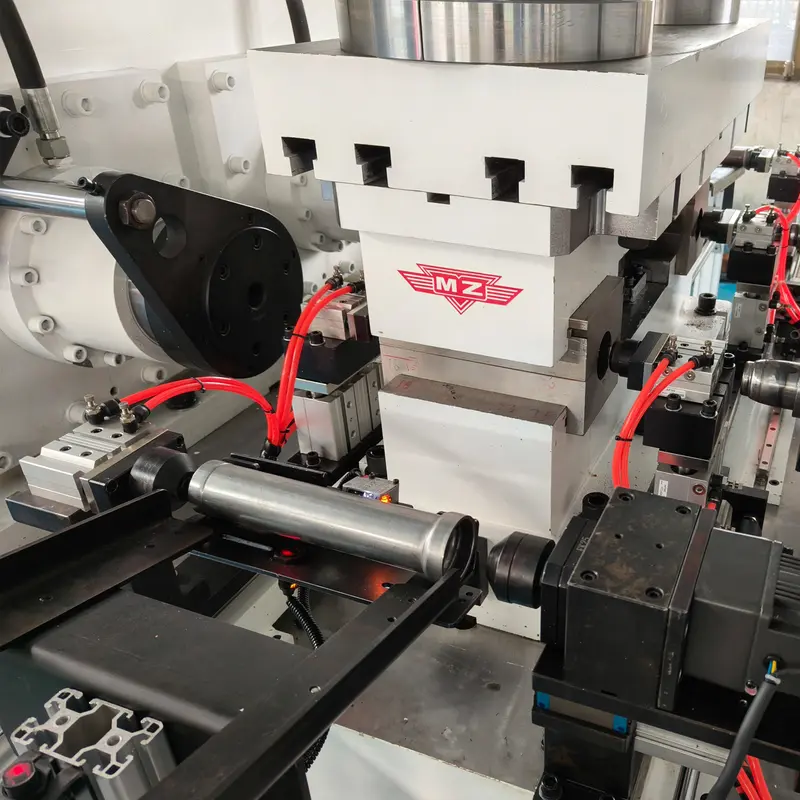

Shrinking and Expanding Pipe Machine Assembly Line

Shrinking and Expanding Pipe Machine Introduction

* Precision and Consistency: Servo-driven controls and intelligent systems ensure uniformity in every processed piece.

* Versatility: Supports reducing, expanding, and forming operations, accommodating different materials and pipe specifications.

* Energy Efficiency: Optimized energy consumption reduces operating costs while minimizing waste.

* Ease of Use: Intuitive control interface and fully automated processes lower the technical requirements for operators.

* Smart Control Interface: Combines PLC and touchscreen controls, enabling parameter settings, real-time monitoring, and quick program switching for various processing needs.

* Real-Time Monitoring and Alarms: Built-in sensors and alarm systems detect equipment issues promptly, ensuring safe and uninterrupted operation.

* Expandable Functionality: Interfaces are available for integration with enterprise production management systems, enabling fully automated production chains.

* Reducing and Expanding Molds: The pipe Machine is made from high-quality alloy material, the mold is durable and suitable for high-intensity operations. It is designed for quick replacement to accommodate various pipe diameters and shapes.

* High-Precision Guide Rails: Equipped with precision guide systems to ensure smooth operation and accurate forming results.

* Hydraulic Clamps: Automatically adjust clamping force to secure pipes during processing, ensuring stability and accuracy.

* Automatic Feeding System: Servo motor-driven mechanism for precise pipe positioning and alignment during operation.

* Efficient Cooling System: Maintains optimal temperatures during operation to prevent damage to molds and pipes.

* Automatic Lubrication: Periodically lubricates key components, reducing wear and prolonging equipment lifespan.

-

Contact

- WhatsApp

Whatsapp: +86-13901566802