Steel Bending Machine | MZ168NC

Steel Bending Machine

● NC Control: Smart control with multi-program and multi-angle settings for easy operation.

● High Precision: Accurate multi-angle bending with consistent precision.

● Efficient & Stable: Supports continuous operation with stable performance.

● Durable Build: Strong materials and components ensure long service life.

● Safe Operation: Safety features prevent misoperation and ensure operator safety.

● Wide Application: Ideal for steel, metal, and alloy pipe bending in various industries.

A steel bending machine with a PLC or IPC manages Feeding (Y), Rotation (B), and bending (C) in a complete automatic cycle.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

Feeding (Y-Axis): Controlled by Servo motor.

Ensure efficient and precise operation during the bending process to meet various processing needs.

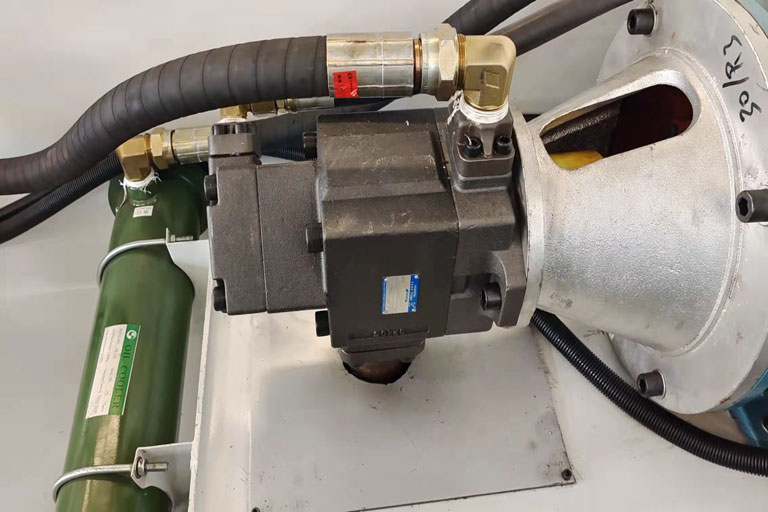

We only use world-famous, popular-quality components in the production of our bending machinery: Japan Mitsubishi Servo, Hydraulic Germany Rexroth, Electrical France Schneider, Seal ring Japan NOK, CNC Controller Siemens or Japan Mitsubishi, and so on.

Europe design structure with higher precision and speed. keep the machine used for a long time.

● Fully hydraulic movement on clamp die, pressure die, and mandrel.

● Available pipe material: steel, stainless, aluminum, titanium, and brass...

● Available pipe shape: Round, Square, Rectangle, Oval, Solid Bar, other profiles...

● Equipped with Japan Omron encoder ensures the accuracy and stability of bending.

Our steel bending machine offers high precision, flexible processing capabilities, and superior surface finishing, meeting the diverse material and product requirements to ensure high-quality finished products.

Specification

| NO. | Name | Parameter | Unit | Remark |

| 1 | Max bending size | Φ168×12 | mm | CARBON STEEL |

| 2 | Max bending radius | R750 | mm | Customized |

| 3 | Min bending radius | According to OD | mm | |

| 4 | Max bending angle | 190 | degree | |

| 5 | Control system | NC | ||

| 6 | Max mandrel length | 5000 | mm | Customized |

| 7 | Number of bends for pipe fittings | 16 | PCS | |

| 8 | Number of parts that can be stored | 16 | group | |

| 9 | Motor power | 22KW | Wuxi Taihu | |

| 10 | Maximum system pressure | 16 | MPa | adjustable |

| 11 | Hydraulic system control | solenoid directional valve | ||

| 12 | Oil tank | 650 | L | homemade |

| 13 | Machine size | 7100×2200×1800 | mm | |

| 14 | Machine weight | 12000 | KG |

video

-

Contact

- WhatsApp

Whatsapp: +86-13901566802